In cream cheese manufacturing, the texture and consistency of the final product are key to meeting the needs of both consumers and manufacturers. At Gelymar, we understand the importance of producing cream cheese that is smooth, firm, easy to spread, and that retains its properties even after going through complex industrial processes such as freezing and thawing. That’s why we’ve developed two innovative products: Gely® Alg DCR 9120 and Gely® Alg DPC 9138, designed to revolutionize cream cheese production with adaptable and effective solutions.

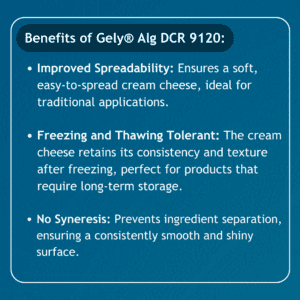

Gely® Alg DCR 9120: Enhances spreadability and cold tolerance

One of the biggest challenges in cream cheese production is maintaining a smooth and spreadable texture after processing, especially when subjected to freezing and thawing cycles. Gely® Alg DCR 9120 excels in this area.

This product is designed to improve the spreadability of cream cheese, ensuring that the final product is always smooth and easy to spread, regardless of storage methods. Additionally, it has a high tolerance to freezing and thawing cycles, ensuring that the cream cheese maintains its perfect texture and appearance without any signs of syneresis or lumpiness, even after undergoing cold storage processes.

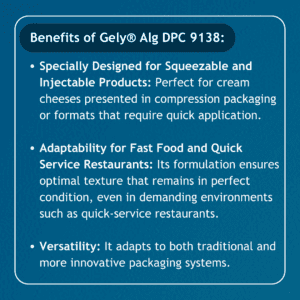

Gely® Alg DPC 9138: The ideal Solution for “squeezable” products and fast food Markets

With the rise of Fast Food and Quick Service Restaurants markets, cream cheese manufacturers are facing new demands. Consumers are looking for products that are easy to use, versatile, and that maintain their quality even in innovative formats such as squeezable or injectable presentations. This is where Gely® Alg DPC 9138 comes into play.

This product has been specially formulated to create cream cheese products that maintain a firm yet flexible texture, making it ideal for squeezable and injectable products. Its ability to adapt to different packaging and presentation systems is a major advantage for manufacturers catering to the growing fast food market, where speed and ease of use are essential.

Why choose Gely® Alg DCR 9120 and Gely® Alg DPC 9138?

With Gely® Alg DCR 9120 and Gely® Alg DPC 9138, cream cheese manufacturers can ensure a firm, creamy, and easy-to-spread texture that not only enhances the quality of the final product but also optimizes production processes. These products offer solutions tailored to current market needs, whether for traditional formats or innovative ones like “squeeze” systems. Additionally, they guarantee perfect consistency without the bothersome separation of ingredients and provide a smooth, shiny surface that improves product presentation.

If you’re looking to innovate and improve your cream cheese manufacturing processes, Gelymar has the perfect solution. Whether your product is aimed at the traditional consumer market or fast-food restaurants, Gely® Alg DCR 9120 and Gely® Alg DPC 9138 are your best allies for achieving superior quality cream cheese.